#4

Influence of Cast Magnetic Alloy Keeper Thickness

on the Attractive Force of a Magnetic Attachment

|

| |

| T. Iwai, Y. Nakamura, K. Shoji, T. Masuda, R. Kanbara, T. Miyata,

M. Sakane, Y. Ohno, Y. Tanaka |

| |

Removable Prosthodontics, School of Dentistry, Aichi-Gakuin University

|

|

| |

| Introduction |

Magnetic attachments which have multiple features such as

smaller size, a stable retentive force, and an improved operability, have

become widely available thanks to the clinically-based research. The conventional

magnetic attachment consists of a magnetic assembly and a keeper. Using

a conventional magnetic attachment often involves some difficulty in designing

a prosthesis due to the restrictive flexibility of the keeper. Attract

P (TOKURIKI-HONTEN Co.) is the only commercially available moldable magnetic

alloy that attaches to a magnet. The use of Attract P for the fabrication

of a keeper may allow the expansion of the magnetic attachment application.

However, few studies are available in the literature on the mechanical

properties of Attract P. The basic data of Attract P is required to use

this alloy for the extensive variety of prosthetic designs.

In the present study, we fabricated keeper prototypes with

the same planer morphology as GIGAUSS C 600 and with a thickness between

0.2 mm and 1.8 mm using Attract P. The attractive force of the keeper prototype

and magnetic assembly was measured, and compared with that of a GIGAUSS

C 600 keeper.

|

| |

Objectives

|

| The purpose of the present study was to evaluate the effect

of keeper design using cast magnetic alloy “Attract P”, and investigate

the relationship between the keeper thickness and attractive force. |

| |

|

| Materials |

| |

|

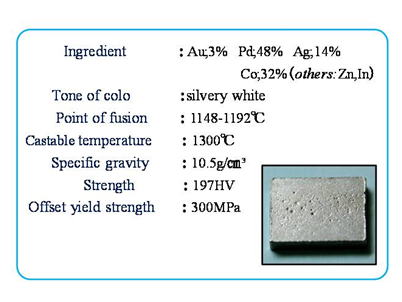

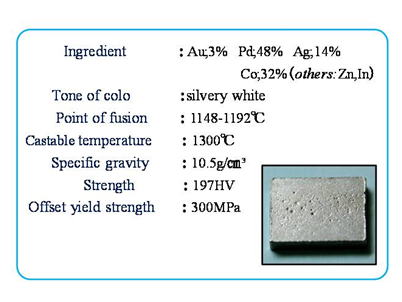

Table 1 shows the mechanical properties of Attract P. Attract P is a Type III gold alloy. The mechanical properties of this alloy include magnetic attraction as well as having high ductility. The entire surface of a keeper fabricated from this alloy has magnetic attraction potential, and, therefore, there is great design flexibility with the “Attract P” alloy use. |

| Table. 1:「Attract P」(TOKURIKI-HONTEN) |

|

|

| |

| Methods |

| |

|

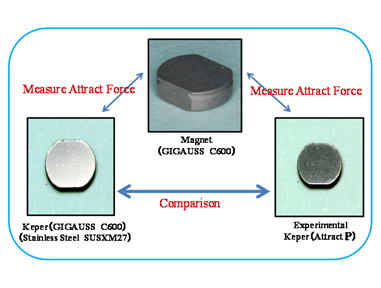

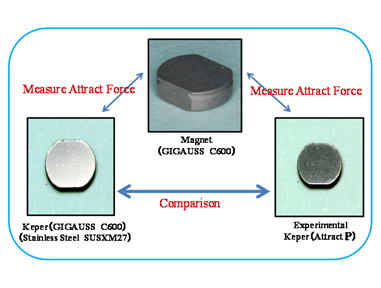

Cast test sample keepers were prepared with Attract P alloy. They keeper samples had an identical planar shape as a conventional keeper (GIGAUSS C 600) for comparative purposes. The fabricated keeper thickness varied from 1.8 to 0.2 mm. Attractive force measurement between a magnetic assembly and the test keepers were then measured, and compared with the result of the attractive force between the standard magnetic assembly and the conventional GIGAUSS C 600 keeper design. Six samples of each were fabricated under identical conditions to test reproducibility. |

| Fig .1: A flow chart of study |

1. Fabrication of samples

1) Pattern fabrication

| |

Two GIGAUSS C 600 keeper trays (GC) were prepared for each sample. Inlay

wax was poured into the trays. Two tray were combined, and the attractive

force side wax surface was polished. Ready casting wax R32 and R40 (GC)

was used as a sprue (Figures. 2 and 3). |

|

|

|

| Fig .2:

two Keper trays

|

Fig .2:

sprued the Keper trays

|

| |

2) Casting

| |

The

wax pattern was invested with phosphate bonded investment CERAVEST (GC), and

cast in the ceramic crucible at 1300 degrees following the conventional method

using a vacuum casting machine |

|

CASCOM (KDF) (Fig. 4). CASCOM (KDF) (Fig. 4). |

|

| Fig .4:

Casting

|

Fig .5:

Experimental Keper of Attract P

|

| |

| |

3) Recontouring and polishing

| |

The oxide layer was removed by air abrasion with aluminum oxide particles after casting, followed by recontour polishing. The external morphology and surface areas of both the marginal and non-attractive faces were adjusted to match the comparative sample keeper size (GIGAUSS C 600). Samples were polished under running water, and cleaned ultrasonicically (Fig. 5). |

|

| |

2. Attractive force measurement

| |

Attractive force measurements were performed using a compact table-top

universal tester machine (SHIMAZU) (Fig. 6). A custom made jig and mold

devised in our department were used to stabilize and maintain the samples

during measurement. Attractive forces were measured 10 times for each sample

at 5 mm/min crosshead speed. Test sample thickness was sequentially reduced

by grinding removal of the non-attractive face with a # 100 wet-dry sandpaper.

Surface parallelism was confirmeded and measured using a seven-point

method to ensure parallel thickness of the samples tested (Fig. 7). Samples

were polished with a grinder “ECOMET 3” to # 1000 until mirror-like surfaces

were obtained, followed by the final buff polished finish. Attractive forces

of finalized samples were measured. This process was repeated for each

of the 6 samples until the minimum thickness of 0.2 mm was achieved and

tested (Fig. 8). |

|

|

|

|

| Fig. 6: EZ test |

Fig. 6: EZ test |

Fig. 8: Flow chart of study |

| |

|

|

| |

| 3. Statistical analysis |

| |

One-way analysis of variance and multiple comparison using Sheffe’s test

were performed at the significance level of 5%. Statistical analysis software

(Dr. SPSS II for Windows standard version, SPSS) was used for the analysis. |

|

| |

|

| Results |

| |

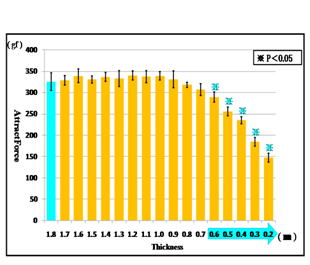

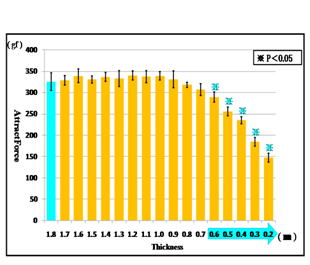

| Keeper samples of sequentially different thickness were prepared with cast magnetic alloy “Attract P”, and the attractive forces of each sample were measured. Fig.9 shows the relationship between the sample thickness and mean attractive force of 6 samples. No significant difference was observed at a significant level of 5% in samples of 1.8 -0.7 mm thickness. Attractive force started to decrease with a decreasing sample thickness from 0.7 mm, showing statistically significant difference. The attractive force of 330 – 340 gf was maintained in samples of 0.7 mm or more. The attractive force measured was 65% of a comparative GIGAUSS C 600 keeper. The results suggested that this alloy has an inflection point at 0.7 mm thickness.

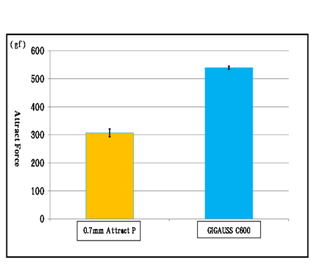

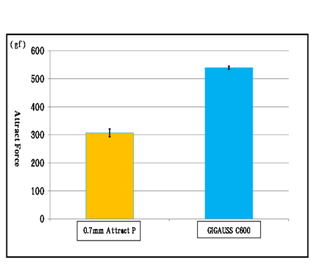

Fig.10 shows the comparison of the attractive force between Attract P and GIGAUSS C 600. We focused on 0.7 mm thickness Attract P since it is the same thickness as GIGAUSS C 600. The attractive force of Attract P was 60% of GIGAUSS C 600 keeper sample.

|

| |

|

|

| Fig.9:Relations between Thickness and Attract Force |

Fig.10:Attract Force of Experimental Keper and GIGAUSS |

| |

|

| |

| Conclusion |

| |

Attract P is moldable magnetic alloy that may be used for keeper attachment to a magnet in clinical practice. The result of the present study demonstrated that the attractive force of Attract P alloy was 60% of GIGAUSS C 600 keeper. However, the comparative actual total space clearance requirement of GIGAUSS C 600 is 1.3 mm including extra consideration for a cast holding support for the keeper. The measured Attract P attractive force at a 0.7 mm thickness was found to be 31 gf. The application of this material may be useful for clinical requirements of minimal space clearance such as application on vital teeth.

|

| |

| References |

1. Y.kiuchi:Magnetic Devices for Retaining Dental Prostheses,Bioinstrumentation

and Biosensors (Ed.D.L.Wise),pp.145-164,1991(Marcel Dekker,Inc)

2. Okuno,O.,Ishikawa,S.,Iimuro,F.T.et al.:Development of sealed cup yoke

type dental magnetic attachment,Dental Materials Journal,10(2):172-184,1991.

3. Y.Terao, Y.Nakamura, T.Ishida, A.Ando, H.Nakamura, et : Measuring Methods

of the Attravtive Force of Magnetic Attachment 16(2) :14~19, 2007. |

|

CASCOM (KDF) (Fig. 4).

CASCOM (KDF) (Fig. 4).