4. Influence of the

heating on the attractive force of a magnetic attachment

-Part 2. Study of

Denture Based Resin Curing-

Miyata

T., Nakamura Y., Niimi J., Ando A., Shouji k., Imaoka S., Ohno Y., and Tanaka

Y.

Removable

Prosthodontics,

Introduction

A magnetic

attachment has achieved excellent clinical results, and has been recognized as

a useful tool with numerous advantages compared with a conventional mechanical

retainers1-3).

A Neodymium

(Nd) magnet, recently available on the market, has a reported characteristic

the temperature-related of magnetic force loss at low relative

temperatures. This is considered as

one disadvantage of a Nd magnet use.

The clinical

use conditions including the effect of temperature relationship and laboratory

processing should be evaluated.

Objective

We

investigated the influence of the difference in curing methods and thickness of

denture-base resin on the attractive force of a magnetic attachment on the

assumption that magnetic assemblies were incorporated into the work model

during polymerization temperatures.

Materials and Methods

1)

Materials

Specified magnetic

assemblies and keepers were used as samples in this study (GIGAUSS D 600 (GC)

and PHYSIO MAGNET 35 (Hitachi Metals)).

Five samples for each product were evaluated(Fig. 1).

Fig. 1: Magnetic attachments

2)

Methods

The influence of two

different resin curing protocols were tested on magnetic attachment attractive

force: 1. microwave curing method and 2.wet heat curing method.

Resin curing protocol

with magnetic attachments followed the following techniques. Microwave technique resins were cured in

a specified microwave oven at 500 watts for 3 minutes. Wet heat resin curing protocol were

cured at 70°C for 60 minutes, and then 100°C for 30 minutes, followed by

cooling at room temperature for 24 hours.

Following use of either curing method, tested magnetic assemblies were

removed from resin samples, and attractive force was measured. Attractive forces before and after

polymerization for each curing method were compared to investigate the

influence of polymerization on the attractive force. We also investigated the change in the

attractive force for 3 different resin thicknesses.

3)

Sample preparation

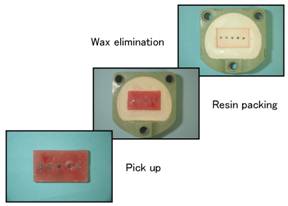

Molded paraffin wax was

invested in a flask using ADVASTONE (GC) based on the conventional method,

followed by wax elimination. A

magnetic assembly was adhesively stablized with alpha-cyanoacrylate adhesive

(Aron Alpha) into the space created by wax elimination. Acron MC Live Pink no. 8 was packed into

a flask in the rapid heat cure method, and Acron Live Pink no. 8 was packed in

the wet heat cure method. A

magnetic assembly was removed from the resin plate after polymerization, and

used as a sample (Fig. 2). Resin

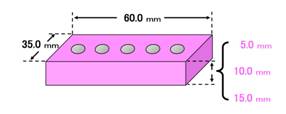

plate samples were 35 x 60 mm in width, and 5, 10, and 15 mm in thickness (Fig.

3).

Fig. 2: Process of sample fabrication Fig. 3: Resin plate size size

4)

Attractive force measurement

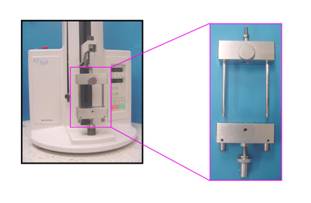

Attractive force

measurement was conducted using EZ test, compact tabletop material tester, with

a 5 kgf load cell and 5 mm/min crosshead speed. Attractive force was measured 10 times

for each magnetic assembly, and the average was taken as a result. Attractive forces before and after each

experiment were compared. The custom made jig devised in our department was used

to accurately measure the attractive force (Fig. 4).

Fig. 4: Measuring device and custom made jig

Results

In the rapid

heat cure method, magnetic attraction forces decreased with both in GIGAUSS D

600 and PHYSIO MAGNET 35 after completion of polymerization procedures. The evaluation of resin thickness on the

attraction forces demonstrated a decrease in measured attraction force with the

resin plate thickness of 10 mm compared to a 5mm sample. No significant difference was found for

the 10 and 15 mm samples (Fig. 5).

The wet heat

curing method showed similar results as the rapid heat curing method regarding

the influence of curing methods and resin thickness (Fig. 6).

Discussion

The present

study was performed on the basis that magnetic assemblies are incorporated into

working models during higher polymerization temperatures. Magnetic assemblies were directly bonded

with a heat-curing resin. Since

this method does not require autopolymerized quick cure resin, it offers

advantages such as improved mucosal surface denture esthetics, and improved

adhesive attachment between a magnetic assembly and resin. Dentures made using

this procedure offer several advantages and improved physical properties with

greater material stability.

The influence

of polymerization on the resulting magnetic attachment attractive force

properties is significant.

Attraction forces decreased both with the rapid heat curing method and

wet heat curing method after polymerization. This finding suggests a

significant heat-related material changes after polymerization.

The magnetic

attachment attraction forces are also affected by enclosing denture resin base

thickness. Further investigation in the relationships of heating on the

magnetic assembly units is recommended.

The mechanisms of heat generation and polymerization on the attractive

force are not clearly understood.

It is also unclear as to the influence of electromagnetic microwave

generation on magnetic assemblies and metal components.

Conclusion

The influence of two different denture

resin curing protocols of the denture base resin, and the effect of resin

thickness on the attraction force was evaluated.

1.Both

the microwave and wet heat curing methods showed a decrease in the attraction

force after polymerization.

2.The

attractive force decreased by 4% in a resin plate 5 mm in thickness, and by 10%

in a resin plate 10 mm in thickness.

No difference was found between resins 10 and 15 mm in thickness.

3.No

significant difference in the attractive force of a magnetic assembly was found

between rapid and wet heat resin curing techniques.

Reference

1.

2. Tanaka, Y.: Dental Magnetic

Attachment, Q&A, Ishiyaku Publishers, Inc.(

3. Nakamura, K. Hiroshi, M. Fukazawa, N.

and et al: Influence of Heat Treatments on Attractive Force of Magnetic

Attachments. J J Mag Dent. 6: 63-70, 1997.