16. Management for a spillway on the Denture fixing the Magnetic assembly

Satomi Tadokoro1, Tetsuo Ohyama1,2, Tomohiko Ishigami1,2, Kenji Otani1,2, Yoshitada Umekawa1,2, Shinya Nakabayashi1, and Yutaka Mituhashi1

1Department of Partial Denture Prosthodontics NUSD

2Division of Clinical Research Center NUSD

Introduction

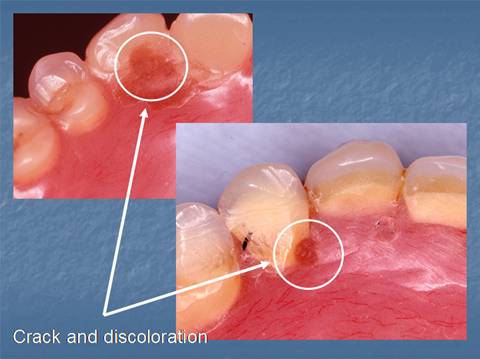

In generally, Denture

was made a spillway for fix the magnetic assembly, using self-curing resin. In

clinical practice, we often notice cracks and discolorations surrounding the

spillway of the denture(Fig1).

Fig1.

Objective

In this study, it was compare with influence of a surface treatment method after push out a self-curing resin from a spillway. These methods were applying light-cured glazing and coating it(NANOCORTⓇ(GC)) on the push out a self-curing resin, and not applying it. The coloration and surface texture was observed after using thermal cycling.

Materials and Methods

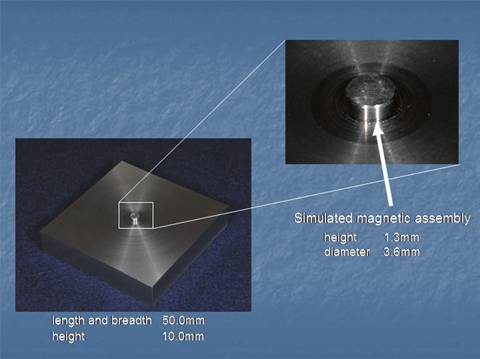

1. A metal model for making sample

The metal model form was a simulated GIGAUSSⓇ D600 (GC). The form is a 50.0mm(length) x 50.0mm(breadth) x 10.0mm(height) pedestal with a 3.6mm(diameter) x 1.3mm(height) column (Fig2.).

Fig2.

2. Preparation of the resin block

A resin block was made a concave from created in it using a plaster spacer(ƒÓ3.9mm x 1.6mm) in a regular polymerizing process using ACRONⓇNo.5(GC) convenience. The manuscripts of the proceedings might be written again by the authors.

3. Management of spillway

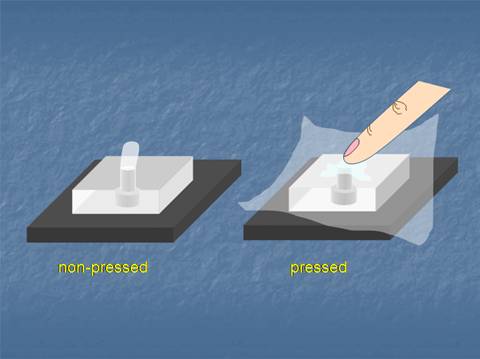

Fig3.

There were two different surface management types with 20 of each specimen.

First, The resin

block was filled up, using brush work, Unifast‡VⓇ(GC) into the concave form. Next,

it was adjusted the resin block with the non-polymerizing Unifast‡VⓇ(GC) to the

metal model. It was confirmed that non-polymerizing resin was push out from the

spillway of the resin block. It was made two groups of specimens using the

polymerizing method surrounding the spillway. These were Non-pressed cure

Group(NPG) and Pressed cure Group(PG) by a finger pressure through the

polyethylene sheet(Fig3.). Both group of specimens were polished by

water-resistant sandpaper made by MALTO Inc.

Fig4.

Ten specimens were made with NANOCORT processing to NPG and ten to PG respectively. We made four types of specimens (NPG-NANOCORT, NPG-NonNANOCORT, PG-NANOCORT, PG-NonNANOCORT), each made up 10 of samples. A micro brush has used to apply NANOCORT to the resin surface. Light curing was effected using LabolightⓇ(GC) (Fig4.).

Both surface properties were observed using SurfcomⓇ(TokyoGiken Inc.) before the thermal cycling procedure and after. Thermal cycling was carried out 10,000 times, using temperatures at 4 degrees and 60 degrees Centigrade.

Results

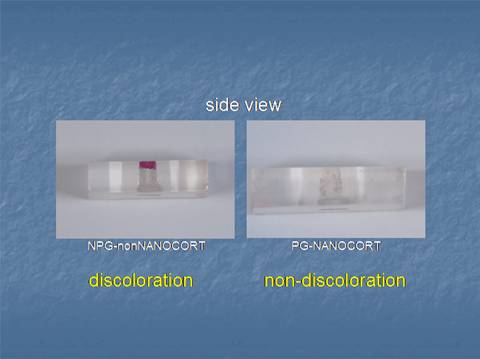

Fig5.

This shows discoloration

on the flank(Fig5).

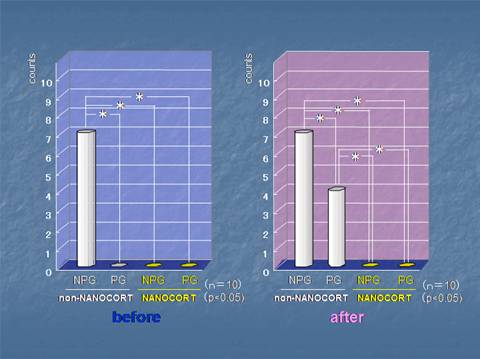

Fig6.

This shows the level

of discoloration before and after the thermal cycling procedure(Fig6.). After

the thermal cycling procedure, the stain solution goes deeply into the gap

between the heat-cured and the self-cured resin surrounding the spillway.

Fig7.

This shows

results of discoloration on the flank(Fig7.). Before thermal cycling procedure,

there is no discoloration on PG and NPG-NANOCORT. After thermal cycling

procedure, there is more discoloration on NPG-NonNANOCORT. There is no discoloration

on PG and NPG-NANOCORT. Compared before the thermal cycling and after, there is

more discoloration on PG-NANOCORT.

When the magnetic assembly was fixed to the denture, it was made a significantly gap surrounding spillway with a self-curing resin as usual. However, there were a significantly gap in PG. In this study, when the magnetic assembly was fixed with a self-curing resin under pressure, it works well for cracks and discolorations surrounding spillway of the denture than no-pressure. Because, a self-curing resin under pressure was cured better than under no-pressure. And using light-cured glazing and coating material, it works better than PG. Because spillway was covered with an adhesion material of NANOCORT labⓇ(GC).

Conclusions

1. When the magnetic assembly fixed in the denture, it is a valid method to use a light-cured glazing and coating material for the self-curing resin surface surrounding the spillway.

2. The magnetic assembly was fixed with a self-curing resin under pressure, where it was possible to fix the assembly without making a significant gap.

References

1. Shinya Nakabayashi, Regarding relations between the amounts of cold-curing resin used for attaching a magnet structure and suction power, JJ Mag Dent 14(5):14-17,2005

2. Toyoda Y, The effect of the pressurization in the polymerization of the cold-cured resin, JJ Pros. Soc 51(2):381,2007(abstract, in Japanese)