Laser penetration into cast Fe-Pt magnetic

alloy and Co-Cr alloy

Jie Liu1, Ikuya Watanabe2, Yasuhiro Tanaka1, Kunihiro Hisatsune1, Mitsuru Atsuta1

1 Department of Developmental and Reconstructive Medicine

2 Department of Biomaterials Science,

INTRODUCTION

Castable Fe-Pt magnetic attachment system has been developed for possible application in dentistry.1,2 The cast Fe-Pt attachment developed was then applied for patients with microstomia and was reported to be favorable results.3,4 In these cases, the cast Fe-Pt keepers were incorporated into Co-Cr metal frameworks by laser-welding since the laser welding has less effects of heating which cause the degradation of magnetic properties for the Fe-Pt alloys. During the procedure to construct the Fe-Pt/Co-Cr assembly, it was hard to choose the intensity of parameters for laser-welding apparatus since little information is available for laser penetration into the Fe-Pt alloy.

OBJECTIVE

The

objective of this study was to examine the laser penetration into cast Fe-Pt magnetic alloy and

compared with that into Co-Cr alloy.

MATERIAL AND METHODS

Cast blocks (20 x 5 x 5 mm) were prepared using a custom made Fe-Pt alloy (Fe-36at%Pt) and a Co-Cr alloy (Cobaltan, Shofu Inc.). After the cast surfaces were air-abraded with 50 µm Al2O3, two cast blocks were butted against one another on the 20 x 5 mm surfaces. They were then perpendicularly laser-welded at their interface using Nd:YAG laser (Tanaka TLL7000) under the following parameters: current of 160 - 300 A (increments of 20 A), spot diameter of 0.4 - 1.6 mm (increments of 0.2 mm) and pulse duration of 1 - 13 ms (increments of 3 ms). Laser welding was conducted under argon atmosphere. After the welded blocks were mechanically separated, the penetration depth (n=3) of the laser into each alloy was measured using computer graphics.

RESULTS

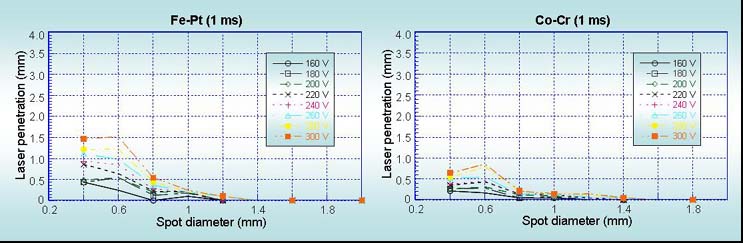

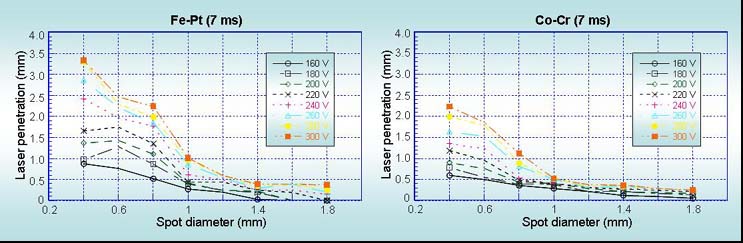

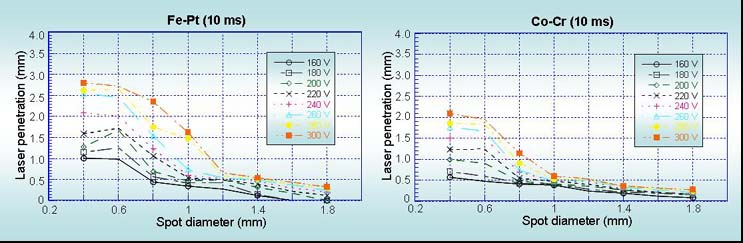

The laser penetrations into

both alloys using pulse durations of 1 ms,

4 ms, 7 ms, 10 ms and 13 ms were presented in Figs 1 – 5,

respectively. Increase in voltage and decrease in spot diameter increased the

laser penetration into both alloys. The laser penetration into Fe-Pt alloy was greater than that into Co-Cr

alloy at any welding parameter, especially at higher current and smaller spot

diameter in each pulse duration.

CONCLUSIONS

The

present study could show the basic data to laser-weld cast Fe-Pt metal

frameworks to Co-Cr frameworks.

REFERENCES

1. Watanabe

I, Tanaka Y, Fukunaga H, Hisatsune K, Atsuta M (2001). Attractive

force of castable iron-platinum magnetic alloys. Dent Mater 17:197-200.

2. Watanabe

I, Hai K, Tanaka Y, Hisatsune

K, Atsuta M (2001). In vitro corrosion behavior of cast

iron-platinum magnetic alloys. Dent Mater 17:217-220.

3. Watanabe I, Tanaka Y, Ohkubo C, Miller A (2002). Application of cast magnetic attachments to sectional complete dentures for a patient with microstomia: A clinical report. J Prosthet Dent 88:573-577.

4. Ohkubo

C, Watanabe I, Tanaka Y, Hosoi T (2003). Application of cast iron-platinum

keeper to a collapsible denture for a patient with constricted oral opening: A

clinical report. J Prosthet Dent 90:6-9.

Figure 1. Laser penetration into Fe-Pt and Co-Cr at a pulse duration of 1 ms.

Figure 2. Laser penetration into Fe-Pt and Co-Cr at a pulse duration of 4 ms.

Figure 3. Laser penetration into Fe-Pt and Co-Cr at a pulse duration of 7 ms.

Figure 4. Laser penetration into Fe-Pt and Co-Cr at a pulse duration of 10 ms.

Figure 5. Laser penetration into Fe-Pt and Co-Cr at a pulse duration of 13 ms.