Application of cast iron-platinum keeper to

collapsed denture for a patient with constricted oral opening: A case

report

Chikahiro OHKUBO, DMD, PhD1, Yoshihiro MAEDA, SDT2,

Ikuya WATANABE, DDS, PhD3, Naoki BABA, DDS, PhD4,

Yasuhiro TANAKA, BS, MS5, Toshio HOSOI, DDS,

PhD6

1Instructor,

Department of Removable Prosthodontics, Tsurumi University School of Dental

Medicine

2Instructor, The Dental Technician Training Institute,

Tsurumi University School of Dental Medicine

3Assistant Professor,

Department of Biomaterials Science, Baylor College of Dentistry, Texas A&M

University System Health Science Center

4Visiting Scientist,

Department of Biomaterials Science, Baylor College of Dentistry, Texas A&M

University System Health Science Center

5Instructor, Department of

Biomaterials Science, Nagasaki University Faculty of

Dentistry

6Dean, Tsurumi University School of Dental

Medicine

Chikahiro

Ohkubo

Department of Removable Prosthodontics

Tsurumi University School of

Dental Medicine

2-1-3 Tsurumi Tsurumi-ku

Yokohama 230-8501, Japan

PH:

+81-45-581-1001

Fax: +81-45-573-9599

e-mail: Okubo-c@tsurumi-u.ac.jp

Corresponding

author

Introduction

Dental practitioners must occasionally treat patients

with constricted oral openings that are caused by temporomandibular joint (TMJ)

dysfunction syndrome, rheumatoid arthritis, or damage to the masticatory muscles

by craniotomy.1 As the size of the oral opening decreases, the

difficulty of the required treatment increases. In cases when the opening is

less than 20 mm, most dental instruments cannot be inserted into the

mouth.2 Even if the patient can open his/her mouth to 30 mm, it is

very difficult to insert or remove a large conventional removable partial

denture (RPD) or complete denture (CD). There have been several

reports3-11 regarding prosthodontic treatment for medically

compromised patients, including patients with limited intraoral access

(microstomia, resected cancer patients, etc.). Sectional dentures and/or

collapsed dentures have usually been prescribed for these

patients.3,5,8,11 A hinge is used to connect the segments of such a

collapsed denture system.3,11 Other methods of assembling the two

segments of sectional dentures are clasps,3-5 cast locking

recesses,5 swing-lock attachments,11 pin

attachments,8 and a telescope system.11

Recently an

attachment system using magnets has been developed, and several types are

commercially available for retention of overdentures or implant-retained

prostheses.12-14 Also it has been found that Fe-Pt alloys have

magnetic properties, and the possibility of applying them to dentistry has been

investigated. Watanabe et al.13 reported that cast Fe-Pt keeps yield

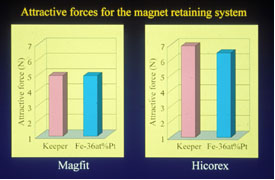

great attractive force to dental Fe14Nd2B magnets (Fig.

1). Additionally, Fe-Pt alloys exhibit excellent corrosion resistance because

they contain a large amount of platinum (approximately 70 wt% Pt).14

The great advantage of this system is that they can be cast using a dental

casting machine and any size or shape of keeper can be fabricated. Thin (less

than 1 mm) or specially shaped keepers are needed in each particular

case.

This clinical report describes the application of a Fe-Pt keeper to a

collapsed RPD for a patient with an extremely constricted oral opening.

Fig. 1 Attractive force to dental Fe14Nd2B

magnets

CLINICAL REPORT

The patient was a 69-year-old partially edentulous woman

with missing posterior teeth, namely, two right molars and two premolars, two

left molars, and the first premolar, of the mandibular (eight teeth, #17, #21 to

#27 remained in the mandibular arch) (Figs. 2a-c). Her oral opening had been

gradually constricted by rheumatoid arthritis for approximately 20 years. The

oral opening became even more constricted after amputation of her temporal

muscle by craniotomy for a subarachnoid hemorrhage in October 1999. The size of

the oral opening was less than 15 mm at her first visit to the division of

Maxillo-facial Oral Surgery of our dental school hospital in December 1999. In

this division, the patient was trained for one year at opening her mouth using

an oral expansion device (Figs. 3a, 3b). When she visited the division of

Prosthodontics, she was able to open her mouth approximately 25 mm. She had an

extremely small RPD that was unserviceable when the denture flanges and clasps

were removed.

Figs. 2 a-c Intraoral view of a partially edentulous

patient

Figs. 3 a, b Severely constricted oral opening due to rheumatoid

arthritis and craniotomy.

Impression and wax denture fabrication

Preliminary impressions for both

dental arches were made using a sectional stock tray (Figs. 4a-d). This tray was

developed from a full arch tray sectioned into right and left halves and could

be reconnected using a slide-lock system on the tray handle.17 A

border molding and definitive impression was also made using a sectional custom

tray with slide-lock joint (Figs. 5 a-c).2 The upper and lower jaw

relationship was registered using a sectional occlusion rim with a dowel-pinhole

joint (Fig. 6). The master casts were mounted on an average valued articulator

(Gysi Simplex OU-II, Onuki-Iki, Tokyo, Japan), and the artificial teeth

(Duradent, GC Corp., Japan) were conventionally arranged. The wax denture could

be collapsed on the right denture base with a clip hinge (Binder clip 36,

Kokuyo, Osaka, Japan) as shown in Fig. 7. The feasibility of placement and

removal of the final prosthesis was carefully confirmed using this wax

denture.

Figs. 4 a-d Preliminary impressions were made using a sectional stock

tray

Figs. 5 a-c Definitive impressions was made using a sectional custom

tray

Fig. 6 Jaw relationship was registered using sectional occlusion rim

with a dowel-pinhole joint

Fig. 7 Wax denture collapsed in the right denture base with clip

hinge.

Denture designs

The right distal extension base of the denture was

composed of upper and lower segments, which were collapsed using a hinge

(Swing-lock attachment, Idea Development Co., Dallas, TX) at the edge of the

lingual flange, allowing for insertion into the mouth (Fig. 8). The metal

frameworks of both segments were separately cast with Co-Cr-Ti alloy (Crutanium,

Krup Inc., Essen, Germany). The clearance was too small (approximately 4 mm in

the thinnest region) between the maxillary natural teeth and mandibular residual

ridge to place commercial attachments connecting the two segments. Also the

shape of the keeper fitted to the framework and residual ridge was complicated.

Therefore, a cast Fe-Pt keeper (Fe-66.3 wt% Pt) and the thinnest commercial

magnets available (Hicorex-slim, Hitachi Metals, Japan) were used for this

case.

Fig. 8 Schematic drawing of the right distal base composed of upper and

lower segments, collapsed using hinge.

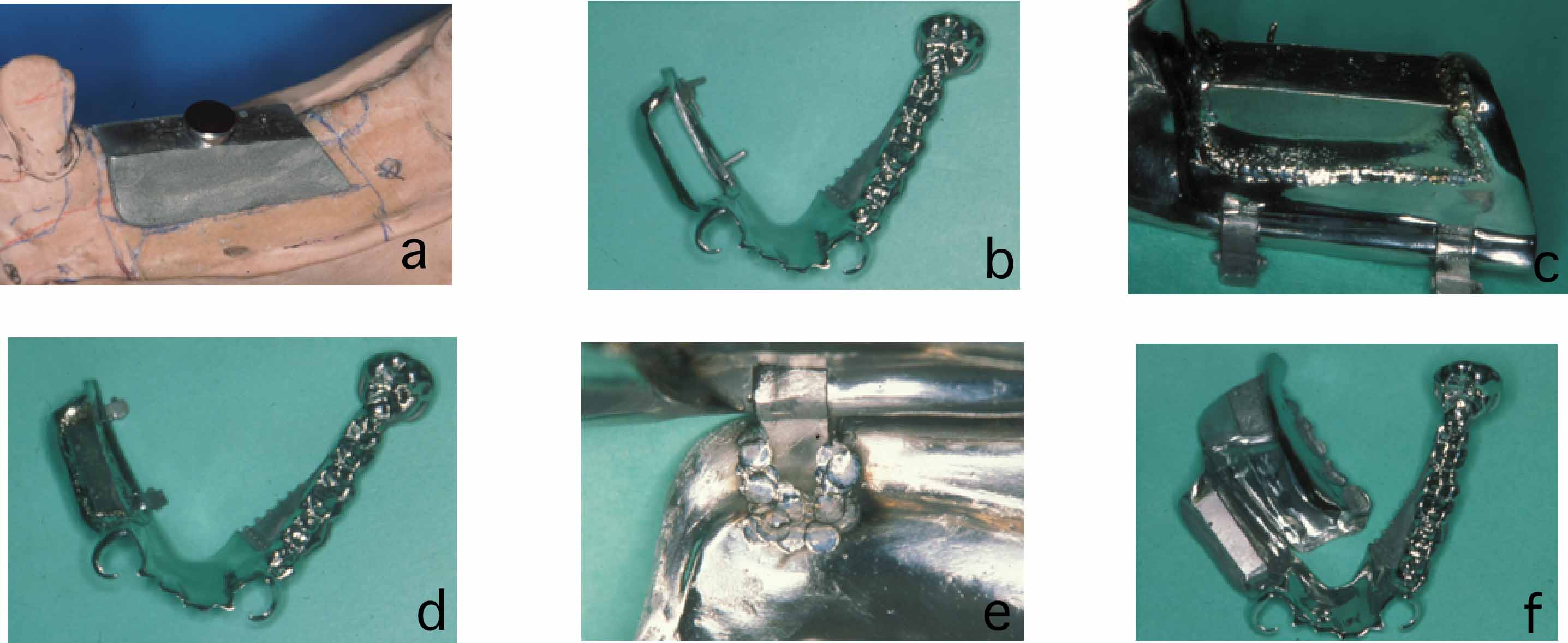

Denture fabrication

The wax pattern for the lower segment including a

plastic pattern of the convex hinge was designed to be assembled with the keeper

and was fabricated on the refractory cast. The pattern was invested (Crutavest,

Krup Inc.,) and cast with Co-Cr-Ti alloy in a centrifugal casting machine (Grove

Cast, Krup, Inc.). After it was desprued and polished, the lower framework was

replaced on the master cast, and the Fe-Pt keeper pattern was then made. The

keeper pattern was invested in a mold with a magnesia-based investment (Selevest

CB, Selec Co., Osaka, Japan) and cast from a custom-made Fe-Pt ingot using a

high-frequency centrifugal casting machine (Jelenko Eagle, Jelenko, NY). After

casting, the Fe-Pt keeper underwent heat treatments in accordance with

procedures reported by Watanabe et al.13,14 The cast Fe-Pt keeper was

then welded to the Co-Cr-Ti lower framework using a laser (neolaser L ALC 30,

Selec Co.). The pattern for the upper segments of the framework with a concave

hinge was fabricated and cast with the same alloy in the same manner as for the

lower framework. After the upper framework was polished, the concavo-convex

hinge was laser-welded to join the two frameworks (Figs. 9 a-f). Denture-base

PMMA resin (Palapress Vario, Heraeus Kulzer Inc, Irvine, Calif.) was polymerized

for the upper and lower segments according to the manufacturer's instructions.

Three commercial magnets (Hicorex-slim) were embedded under the metal teeth in

the upper segment with auto-polymerized resin (Uni-fast 2, GC Corp. ). Figure 10

show the final RPD, which could be collapsed using a lingual flange hinge and

magnetic attachments.

Figs. 9 a-f Assembled framework of upper and lower segments by laser

welding

Figs. 10 a, b Completed RPD could be collapsed using lingual flange

hinge and magnetic attachments.

Delivery of dentures

The denture was inserted in the mouth by collapsing

the right denture base to the lingual side. After being inserted into the mouth,

the upper segment was rotated and connected to the lower segment. The denture

was fitted after it was restored to its original form in the mouth (Figs. 11a,

11b). Figure 12 shows an occlusal view of the denture after placement.

After

an observation period of 1 year and 2 months, the collapsed denture, which was

easily inserted into the mouth, continues to deliver adequate function with no

problem, and the patient is very satisfied.

Figs. 11 a, b Delivery of collapsed denture into the

mouth.

Fig.12 Occlusal view of the lower arch after installation of collapsed

denture.

SUMMARY

This report described a removable collapsed denture connected by

hinges and a magnetic retention system consisting of a cast iron-platinum keeper

and commercial magnet (Hicorex-slim) for a patient with a severely constricted

oral opening. With the use of a cast keeper and flange hinges, the collapsible

RPD was successfully and easily installed, and the patient expressed

satisfaction regarding her masticatory function.

ACKNOWLEDGMENTS

Editorial assistance by Mrs. Jeanne Santa Cruz is

greatly appreciated.

REFERENCES

1) Fricton JR, Kroening RJ, Hathaway KM. TMJ and craniofacial

pain: Diagnosis and management. Ishiyaku EuroAmerica, Inc. S. Louis, 1-11,

1988.

2) Ohkubo C, Maeda Y, Sugiyama K, Suzuki Y, Ishikawa Y, Hosoi T.

Impression techniques for patients with microstomia or constricted oral opening.

Tsurumi Univ Dent J 28: 145-151, 2002.

3) Conroy B, Reitzik M. Prosthetic

restoration in microstomia. J. Prosthet. Dent. 26: 324กม327, 1971.

4) Hagiwara

H, Nakamura H, Matsumura M, Seto K, Abe K, Nomura T. The mouth circumference of

normal adults and patients of microstomia. J Jpn Maxillofacial Prosthet 5:

37-43, 1982.

5) Winkler S, Wongthai P, Wazney JT. An improved split-denture

technique. J. Prosthet. Dent. 51: 276-279, 1984.

6) Luebke RJ. Sectional

impression tray for patients with constricted oral opening. J. Prosthet. Dent.

52: 135กม137, 1984.

7) Whitsitt JA, Battle LW. Technique for making flexible

impression trays for the microstomic patient. J. Prosthet. Dent. 52: 608กม609,

1984.

8) McCord JF, Moody GH, Blinkhorn AS. An overview of dental treatment

of patients with microstomia. Quintessence Int. 21: 903กม906, 1990.

9)

Mirfazaelian A. Use of orthodontic expansion screw in fabricating section custom

trays. J. Prosthet. Dent. 83: 474กม475, 2000.

10) Baker SP, Brandt RL,

Boyajian G. Impression procedure for patients with severely limited mouth

opening. J. Prosthet. Dent. 84:241กม244, 2000.

11) Suzuki Y, Abe M, Hosoi T et

al. Sectional collapsed denture for a partially edentulous patient with

microstomia: A clinical report. J Prosthet. Dent. 84: 256กม259, 2000.

12)

Kurtz KS, Ohkubo C, Watanabe I Shimizu H, Cai Z, Okabe T. Evaluation of magnet

system retaining a midfacial maxillofacial prosthesis. J Dent Res 79: 178(Abstr.

277), 2000.

13) Watanabe I, Tanaka Y, Fukunaga H, Hisatsune K, Atsuta M.

Attractive force of castable iron-platinum magnetic alloys. Dent Mater

17:197-200, 2001.

14) Watanabe I, Hai K, Tanaka Y, Hisatsune K, Atsuta M. In

vitro corrosion behabior of cast iron-platinum magnetic alloys. Dent Mater

17:54-61, 2001.

15) Mastumoto Y, Abe M, Hosoi T, Mizuno Y. Removable

prosthesis using hinge in distal-end for path of insertion. J. Jpn. Soc. Magnet.

Applicat. Dent. 9:17-22, 2000.

16) Mastumura H, Kawasaki K. Magnetically

connected removable sectional denture for a maxillary defect with severe

undercut: A clinical report. J. Prosthet. Dent. 84:22-6, 2000.

17) Ohkubo C,

Ohkubo C, Hosoi T. Development of sectional stock tray system. The Nippon Dental

Review. 61: 103-105, 2001.