INTRODUCTION

Microstomia

is often a sequela of burns, postoperative

head and neck trauma, surgical

resection of facial and oral neoplasms, and

scleoderma.1 The

patients who must wear removable dental prostheses

often complain of an

inability to insert or remove a denture due

to constricted opening. There have

been several reports regarding the fabrication

of removable prostheses for

patients with mictostomia. Some include the

use of Co-Cr frameworks with clasps

to hold sectional complete dentures,2,3 a sectional complete denture

joined by a post that slides into stainless

steel tubing,4 and use

of cast Co-Cr hinges and swing-lock attachments

for removable partial or

complete dentures.5,6 There are few reports about sectional complete

dentures utilizing dental magnetic attachments.

Matsumura and Kawasaki7

utilized a dental magnetic attachment for

a sectional removable partial denture

for a patient with a severe undercut secondary

to ablative tumor surgery. They

reported that the magnetic retention system

is considered to be clinically

useful for interrelating and retaining a

segmented sectional prosthesis.

Currently, there are several commercially

available magnetic attachment systems

for use in clinical dentistry. Recently,

it has been found that Fe-Pt alloys

have magnetic properties,8-10 and they have been investigated for possible

application to

dentistry.11,12 Watanabe et al.13,14 developed the Fe-Pt magnetic

attachment system. They reported that the

cast Fe-Pt keeper yielded great

attractive force to dental Fe14Nd2B magnet.13 Furthermore, the Fe-Pt alloys

exhibit excellent corrosion resistance because

they contain a large amount of

platinum (approximately 70wt% Pt).14 Since the Fe-Pt alloys can be

cast in a dental casting machine, any size

or shape of castable magnetic

attachment can be fabricated for prostheses.

The cost of platinum for custom

magnetic castings is comparable to the cost

of commercially available magnetic

prosthetic components. Clinical indications

include magnetic retention for

conventional intraoral dental prostheses

and intra or extraoral maxillofacial

prostheses. Implant retained maxillofacial

prostheses often have anatomically

confounding factors which require custom

castings to align prosthetic retentive

components and allow a favorable path to

insertion. Kurtz et al.12

have investigated and demonstrated efficiency

of this concept. The custom cast

Fe-Pt magnetic attachment , therefore, has

a variety of custom applications as

compared to the commercially available dental

magnetic attachment.

This

clinical report describes the prosthodontic

treatment of an edentulous patient

with microstomia induced by scleroderma using

cast Fe-Pt magnetic attachments.

CLINICAL REPORT

A

67-year-old edentulous woman with microstomia

induced by scleroderma presented

for prosthetic evaluation (Fig. 1). The diameter and circumference of

her mouth were approximately 32 mm and 95

mm, respectively. The patient had

extremely small complete dentures which were

unserviceable and refused to

undergo surgical enlargement of the mouth

aperture.

Fig. 1. Diameter and circumference of

patient=s mouth was approximately 32 mm and 95 mm,

respectively, because of

scleroderma.

Impression and wax denture

fabrication

Preliminary

impressions with two stock impression trays

of each half of the mouth for both

dental arches, fabrication of sectional custom

trays for the final impressions,

border molding and final impressions were

accomplished according to the

previous reports.6 The jaw relationship was recorded with sectional

collapsed occlusion rims fabricated with

autopolymerizing PMMA base resin (Tray

resin, Shofu Inc., Kyoto, Japan), commercial

dental magnetic attachments

(Hicorex 4513, Morita Corp., Kyoto, Japan)

and clip hinges (Binder clip 36,

Kokuyo, Osaka, Japan). The master casts were

mounted on an average valued

articulator (Dental Hobby, Shioda Co. Ltd.,

Tochigi, Japan), and artificial

teeth (Endura, Shofu Inc., Kyoto, Japan)

were conventionally arranged. The wax

dentures could be sectioned and collapsed

as shown in Fig. 2. The

anterior segments included artificial teeth

of incisors and both canines, and

could be connected to the posterior segments

using dental magnetic attachments.

The posterior segments could be collapsed

using hinges located at the center of

the denture bases. Using the upper and lower

sectional collapsed wax dentures,

the correct jaw relationship was confirmed

in the patient=s mouth. Placement and removal of

the trial prosthesis was rehearsed and with

practice and could be easily

accomplished by the patient.

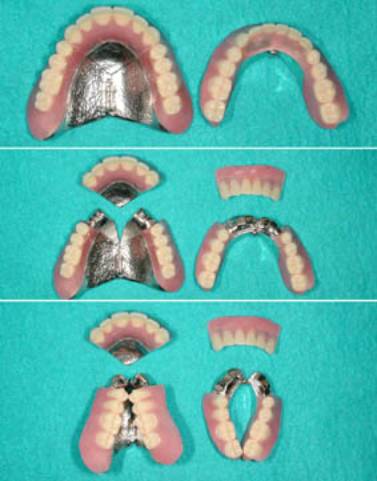

Fig. 2. Sectional collapsed trial dentures fabricated

with clip hinges and dental magnetic attachments.

Denture designs

Each denture was composed of an

anterior and two posterior segments. Anterior

segments include artificial teeth

of incisors and both canines, and cast Fe-Pt

magnet (Fe-69.3%Pt-0.6%Nb).

Posterior segments include bilateral premolars

and molars, and cast Fe-Pt

keeper (Fe-66.3%Pt). Cast Co-Cr (Partial

Denture Alloy, Jelenko, NY) (Co:63.0%,

Cr: 28.5%, Mo:6.0%) metal frameworks were

built into all of the segments except

for an anterior segment of the lower denture.

The Co-Cr metal frameworks of

posterior segments could be collapsed using

the lingual and palatal midline

hinges (Swing-lock attachment, Idea Development

Co., Dallas, TX) which allowed

for insertion into the mouth (Fig. 3). The anterior segments could be

connected to/from the posterior segments

due to the Fe-Pt magnets and keepers.

Fig. 3. Co-Cr metal frameworks that can

collapse using lingual and palatal midline hinges.

Fig. 4. Cast Fe-Pt magnet with concavo design.

Denture fabrication

The

left half wax pattern of the Co-Cr framework was fabricated on a

phosphate-bonded refractory cast (Snow White, Shofu Inc., Kyoto Japan) and the

plastic pattern of the concave hinge cylinder was placed and embedded at the

lingual or palatal midline of the framework wax pattern. The half pattern of

framework and hinge were cast with the Co-Cr alloy using a vacuum induction

casting machine (Argon Caster, Shofu Inc., Kyoto, Japan). After polishing the

cast framework of the left half, the framework was returned on the master cast.

Right half wax pattern of framework and wax pattern of convex hinge were then

fabricated on the refractory cast in which left half framework was embedded,

and cast with the Co-Cr alloy. These procedures followed manufacturer=s instruction for fabrication of the

swing-lock attachment hinge. The patterns of the Fe-Pt keeper were fabricated

on the master cast on which the polished Co-Cr framework has been returned. A

pattern of the Co-Cr framework for anterior segment of upper denture was also

made on the polished Co-Cr framework seated on the master cast and was cast

separately. The patterns of Fe-Pt keeper were invested in a mold with a

magnesia-based investment (Selevest C&B, Selec Co., Osaka, Japan) and cast

with custom-made Fe-Pt ingot using a centrifugal high-frequency casting machine

(Jelenko Eagle, Jelenko, NY). The wax patterns for cast Fe-Pt magnetic

attachment were designed convex for the keeper and concave for the magnet

components (Figs. 3 and 4). This concavo-convex design allows for rigid

connection of the anterior segment to the posterior segment. The patterns of

Fe-Pt magnet were made on the polished cast Fe-Pt keeper on the master cast and

fabricated in the same manner as the Fe-Pt keeper. Figure 4 demonstrates

the Fe-Pt magnets after casting. The Fe-Pt keepers and magnets underwent heat

treatments according to the previous study reported by Watanabe et al13

,14 and Kanno et al.15 The Fe-Pt

magnets were magnetized using a magnetizer

(MSD-200-3500P, Nihonkokan, Tokyo,

Japan) after heat treatment. The cast Fe-Pt

keepers were then laser-welded

(TLL7000, Tanaka Laser Co., Tokyo, Japan)

to the Co-Cr framework as shown in Fig.

3. After the preparation of Co-Cr frameworks

and Fe-Pt magnetic

attachments, denture-base PMMA resin (New

Modern Core, Sankin, Tokyo, Japan)

for the anterior segment and posterior segment

were polymerized separately in

accordance with the manufacturers directions.

The cast Fe-Pt magnets were

embedded in the anterior segments when the

base-resin was polymerized. Figure

5 shows the final complete denture prostheses.

The dentures could be

sectioned and collapsed due to the lingual

and palatal midline hinges and the

Fe-Pt magnetic attachments.

Fig. 5. Final sectional collapsed

complete dentures.

Delivery of dentures

The

patient was given home care instruction on

the operation of the sectional

collapsed complete dentures. Since it is

impossible for the patient to deliver

the dentures into the mouth without sectioning

and collapsing, collapsed

posterior segments are first delivered into

the mouth (Fig.6). Then, the

sectioned anterior segments are delivered

and connected to the posterior

segments in the mouth as shown in Fig. 7. Figure 8 shows a

frontal view of the patient after installation

of upper and lower sectional

collapsed complete dentures.

Fig. 6.

Delivery of the collapsed posterior segments.

Fig. 7.

Delivery of the sectioned anterior segments.

Fig. 8. Frontal view of the patient after installation

of upper and lower dentures.

DISCUSSION

Fe-Pt

dental magnetic attachments are clinically

useful for retention of prostheses

due to excellent attractive force. Since

the attachment keeper is placed onto

the root canal of the abutment tooth or implant

abutment, the size of the

keeper and its magnet are circumscribed by

the size of the abutment tooth or

implant abutment. Therefore, several sizes

of magnets and keepers are available

in prefabricated commercial dental magnetic

attachment systems. However,

prefabricated magnetic components are designed

(flat-on-flat). This allows for

easier displacement by a force parallel to

the flat connection plane. Since the

Fe-Pt magnetic attachment system (magnet

and keeper) can be cast in a dental

casting machine, any size or shape of castable

magnetic attachment can be

fabricated for prostheses. Because of the

castable property of Fe-Pt magnetic

attachment, the wax patterns for cast Fe-Pt

magnetic attachment were designed

convex for the keeper and concave for the

magnet (Figs. 3 and 4). This

concavo-convex design rigidly connect the

anterior segment to posterior segment

and prevents wear of the magnetized components and stress concentration

at the lingual and palatal midline hinge

during chewing functions. This

prevents denture deflection and may minimize

the possibility of breakage.

The

Fe-Pt magnetic attachment (magnet and keeper)

requires heat treatments to

obtain magnetic properties after casting.

The magnetic properties can be

achieved due to the

order‑disorder phase transformation

of the binary Fe‑Pt alloy system.11

The Fe-Pt keeper requires solution heat treatment

to produce the disordered

Fe-Pt atoms. The ordered Fe-Pt magnet can

be acquired by aging heat treatment

after solution treatment. Then, the Fe-Pt

magnet has to be magnetized to

arrange the direction of ordered Fe-Pt atoms.

After obtaining magnetic

properties, other heat effects such as soldering

and brazing reduce the

magnetic properties, resulting in the decrease

of the attractive force between

the Fe-Pt magnet and keeper. Therefore, laser-welding

applied in this case (Fig.

3) is the most favorable method to weld the

Fe-Pt magnet or keeper to the

other alloys. Since laser energy can be concentrated

on a small area, there are

fewer effects of heating and oxidation on

the area surrounding the spot to be

welded.16 If

the Fe-Pt magnets lose magnetic properties

after clinical use due to the

circumferential magnetic field, they can

be remagnetized to restore the

attractive force without any damage to the

denture components.

The

magnetically connected sectional prostheses

described in this clinical report

is convenient for this patient in terms of

insertion/withdrawal, and has

functioned very favorably for a service period

of one year. No visible fracture

or wear has been observed in this magnetic,

hinged, collapsable prostheses.

Follow-up appointments to monitor prostheses

function or treatment

complications will continue.

SUMMARY

This

clinical report described cast iron-platinum

magnetic attachment system applied

to sectional collapsed complete dentures

for an edentulous patient with

microstomia. With the use of the lingual

and palatal midline hinges and Fe-Pt

magnetic attachment, the sectional collapsed

complete dentures could be

successfully and easily installed and delivers

adequate function in the patient=s mouth.

REFERENCES

1. Smith PG, Munts HR, Thawley SE. Local

myocutaneous advancement flaps. Alternative

to cross-lip and distant flaps in the recocstruction

of ablative lip defects. Arch Otolaryngol

1982;108:714-8.

2. Conroy B, Reitzik M. Prosthetic restoration

in microstomia. J Prosthet Dent 1971;26:324-7.

3. Winkler S, Wongthai P, Wazney JT. An improved

split denture technique. J Prosthet Dent

1984;51:276-9.

4. MacCord JF, Tyson KW, Blair IS. A sectional

complete denture for a patient with microstomia.

J Prosthet Dent 1989;61:645-7.

5. Wahle JJ, Gardner LK, Fiebiger M. The

mandibular swing?lock complete denture for

patients with microstomia. J Prosthet Dent

1992;68:523-7.

6. Suzuki Y, Abe M, Hosoi T, Kurtz K. Sectional

collapsed denture for a partially edentulous

patient with microstomia: A clinical report.

J Prosthet Dent 2000;84:256-9.

7. Matsumura H, Kawasaki K. Magnetically

connected removable sectional denture for

a maxillary defect with severe undercut:

A clinical report. J Prosthet Dent 2000;84:22-6.

8. Watanabe K, Masumoto H. On the high energy

product of Fe?Pt permanent magnet alloys.

J Jpn Inst Metals 1983;47:699-703.

9. Watanabe K. Permanent magnet properties

in Fe-Pt-Nb system alloys. J Jpn Inst Metals

1990;54:1284-90.

10. Watanabe K. Permanent magnet properties

and their temperature dependence in the Fe-Pt-Nb

alloy system. Mater Trans JIM 1991;32:292-8.

11. Tanaka Y, Kimura N, Hono K, Yasuda T.

Microstructure and magnetic properties of

Fe?Pt permanent magnets. J Mag Mater 1997;170:289-97.

12. Kurtz K, Ohkubo C, Watanabe I, Shimizu

H, Cai Z, Okabe T. Evaluation of magnet system

retaining a midfacial maxillofacial prosthesis.

J Dent Res 2000;79:178 (Abstr 277).

13. Watanabe I, Tanaka Y, Fukunaga H, Hisatsune

K, Atsuta M. Attractive force of castable

iron-platinum magnetic alloys. Dent Mater

2001;17:197-200.

14. Watanabe I, Hai K, Tanaka Y, Hisatsune

K, Atsuta M. In vitro corrosion behavior

of cast iron-platinum magnetic alloys. Dent

Mater 2001;17:217?20.

15. Kanno T, Nakayama T, Kimura K, Okuno

O. Effect of Si and Nb on Fe-Pt magnetic

casting alloys. J Jpn Soc Dent Mater Dev

1998;17:54?61.

16. Roggensack M, Walter MH, Boning KW. Studies

on laser- and plasma- welded titanium. Dent

Mater 1993;9:104-7.