Retentive Force and Magnetic Flux Leakage of

Magnetic Attachment in Keeper and Castable

Magnetic Alloy.

K. Miyata1, M. Hasegawa1,

Y. Abe1, T. Azuhata1, H. Saito1, M. Morokuma1,

D. Akita1 and

T. Ishigami1,2.

1Department of Partial denture

Prosthodontics, Nihon University School of Dentistry

2Division of Clinical Research,

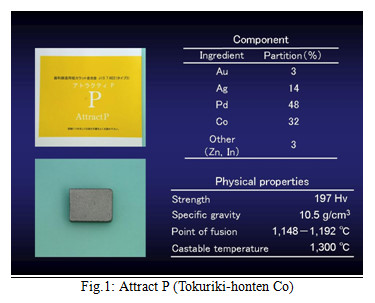

Introduction

The conventional magnetic

attachment consists of a magnetic assembly and keeper, therefore the prosthesis

for abutment has several size restrictions from keeper size. The use of Attract

P (Tokuriki-honten Co) that is new material of castable magnetic alloy for the

fabrication of keeper may allow the expansion of magnetic attachment

application (Fig.1). However, there results about retentive

force of Attract P are not same, because of difference of the test methods, and

there is no report about magnetic flux leakage.

Objective

This study evaluated retentive force

and magnetic flux leakage of Attract P as compare, compared wiht keeper.

Materials and Methods

1. Production of samples

The wax pattern for samples were made with PLATE PARAFFIN WAX (Mutsumi Chemical Industries Co) and SHEET WAX #24 (GC) which size are 6.0~6.0~2.0 mm. The wax patterns were invested with phosphate bonded investment CERAVEST QUICK (GC), and cast in the ceramic crucible at 1300 following the conventional method using a vacuum casting machine. To compare the influence abrasion methods of surface, one group of samples was polished with wet-dry sandpaper to # 2,000 until mirror-like surface were obtained, another group of samples was polished by hand with handpiece iSilicon point M2, M3: SHOFU INC.j which assumed the clinical. The last external form of the sample assumed 5.0~5.0~1.5mm and manufactured by 5 each. Then, GIGAUSS D600 (GC) was selected as a commercial ready-made keeper sample.

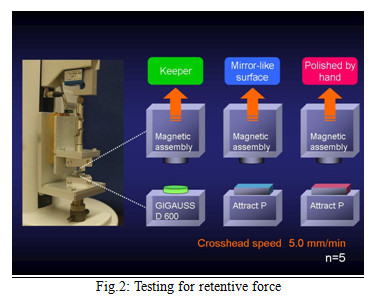

2. Measuring retentive force

Testing for retentive force was made using a linear ball slide (THK Co) set on a universal testing machine (EZ-Test: Shimadzu Co). A sample was attached to the acrylic prism of the jig fixation compartment and then the magnetic assembly was adsorbed to the sample. The magnetic assembly was bonded to another acrylic prism of the jig traction compartment. Retentive forces were measured 5 times for each sample at 5.0 mm/min crosshead speed (Fig.2).

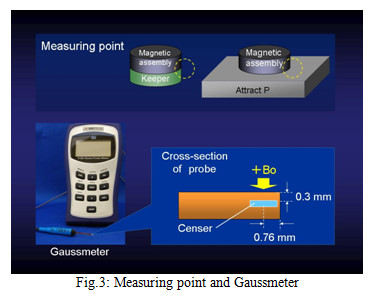

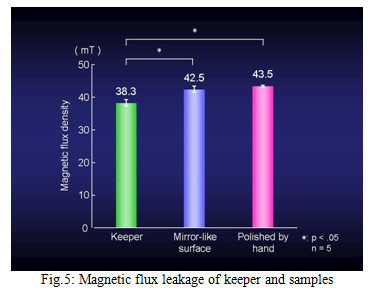

3. Measuring magnetic flux leakage

Magnetic flux

strength was measured using a Hall Effect Gaussmeter (F.W. Bell 5170: TOYO Co) and dedicated measured probe (STB1X-0201: TOYO Co). Magnetic flux

leakage for the adsorbed magnetic assembly and sample measured

at outside of interface of magnetic assembly and samples where was the greatest

value will occur based on prior work (Fig.3).

4. Statistical analysis

Each data was statistically analyzed using a one- way ANOVA, and Tukeyfs HSD post hoc test (¿ = 0.05).

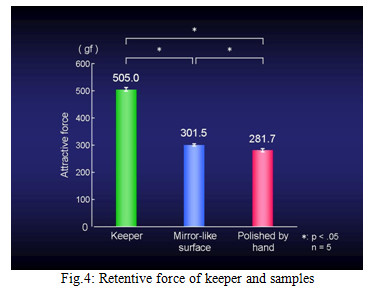

Results and Discussions

Retentive force for keeper and castable magnetic alloy is shown in Fig.4. Retentive force for keeper was 505.1 gf, mirror-like surface was 301.5 gf, and polished by hand was 281.7 gf. The significant differences were noted in the results among all groups of samples. It reasoned that Attract P was lower saturation magnetic flux density than keeper made by stainless steel, and adhesion between magnetic assembly and sample was fallen.

The magnetic flux leakage for keeper and castable magnetic alloy is shown in Fig.5. The significant differences were noted in the results except for between mirror-like surface and polished by hand. Similarly the result of retentive force test, it was considered that magnetic flux leakage was affected by saturation magnetic flux density. Therefore, no significant difference was found for that state of adsorption surface influenced magnetic flux leakage.

Conclusions

1.

The retentive force of Attract P was 60 % of original combination of

GIGAUSS D600.

2.

The difference of the polish method of the retentive surface condition influenced retentive force.

3.

The magnetic flux leakage of Attract P was higher than original

combination.

In this result shows this castable magnetic alloy is not

expected great retentive force to apply for clinical situation.

References

1. Y. Ogawa1, Y. Umekawa1,2, T. Ishigami1,2,et: Effect of Crosshead Speed on Magnetic Retentive Force, The 8th International Conference on Magnetic Applications in Dentistry: #8, 2009.

2. S.Endo1, T.Ishigami1, 2, K.Miyata1, et: Hardening time of Self-curing resin for Installing Magnets and Removing Denture, The 8th International Conference on Magnetic Applications in Dentistry: #10, 2009.

3. T. Iwai, Y. Nakamura, K. Shoji, et: Influence of Cast Magnetic Alloy Keeper Thickness on the Retentive Force of a Magnetic Attachment, The 9th International Conference on Magnetic Applications in Dentistry: #4, 2010.