Influence

of Re-casting on the Attractive Force of Attract P®

K.Yoshihara, T.Iwai, Y.Nakamura,

K.Shoji, Y.Ohno, R.Kanbara, T.Masuda, Y.Tanaka

Department of Removable Prosthodontics,

School of Dentistry, Aichi-Gakuin University

Introduction

@gAttract Ph is a castable

dental alloy with magnetic potential property for use with dental magnetic

attachments. The casting properties

of Attract P permit the application of the alloy for a wide variety of

different configurations and uses as a cast magnetic keeper for the retention

of prosthetic appliances. This material is ideal for customized fabrication of

magnetic attachment keepers intended for space restricted clearance uses such

as restricted occlusal clearance or the use with

vital dentitions.1)

The casting procedure for castable dental alloys may require individual non-contaminated casting ingot use to prevent alloy contaminations that would impair the cast alloy physical properties. Another potential area of cast alloy physical property degradation may be the repeat casting of an alloy also causing changes in physical property. The effect of multiple melt and casting re-use upon magnetic attractive force for this specialized castable alloy has not been reported. No reports have been available regarding the influence of recasting on attractive force have been made.

Objective

Recasting was performed to fabricate a custom-made keeper using a new ingot and melting new alloy ingots. The influence of alloy recasting using a previously cast ingot and cruicible on attractive force was investigated.

Materials and Methods

1. Materials

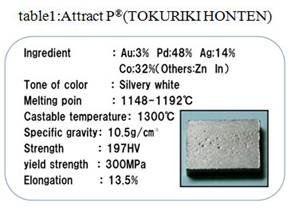

Cast magnetic alloy Attract P® (TOKURIKI-HONTEN Co.) was used (Table 1).

Attract P is the only commercially available magnetic dental casting alloy.

1. Fabrication

of samples

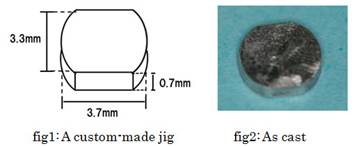

A custom-made jig was fabricated by molding a precast ingot formed during casting (Figures 1 and 2).

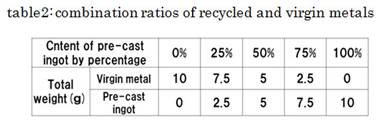

Table 2 shows five combination ratios of recycled and virgin metals, and 5 samples were prepared.

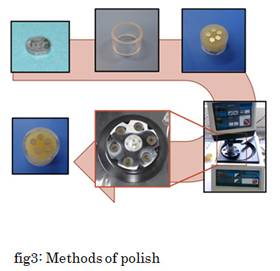

Sand blasting was performed after casting to remove oxide layers. The external morphology and surface areas of both marginal and non-attractive faces were adjusted to match the comparative sample keeper size (GIGAUSS C 600). Samples were embedded in epoxy resin, and attractive faces were mirror-polished using a polishing machine (ECOMET 3, BUEHLER) (Fig. 3).

3. Attractive force measurement

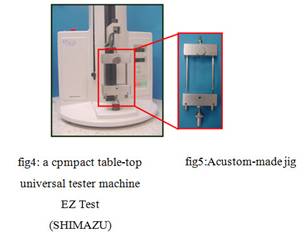

Attractive force was measured using a compact table-top universal tester machine EZ test (SHIMAZU). A custom-made jig and mold (Reference) were used. Attractive force was measured 10 times for each sample at 5 mm / min crosshead speed (Figures 4 and 5).

Results

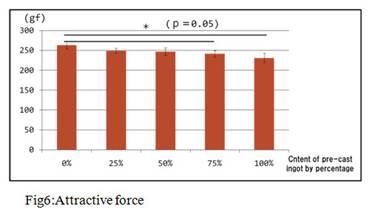

Attractive force of a

magnetic assembly and a keeper decreased with an increase of pre-cast ingot

content (Figure6).

Results were analyzed using one-way analysis of variance and Scheffefs multiple comparison test. A significant decrease in attractive force was observed in samples with 75% and 100% of ingot content compared to a virgin metal sample without pre-cast ingot metal.

Discussions

1.Dental cast magnetic alloy (Attract P)

Eda et al.2) investigated castability, surface and mechanical properties, and texture observation of Attract P, and compared with those of commercially-available dental Au-Ag-Pd and gold alloys. The report stated that element distribution of a casting was relatively constant. However, casting using a pre-cast ingot has not been discussed. TOKURIKI-HONTEN, the manufacturer of Attract P reported that Attract P can be recast without any problems. However, no detailed conditions have been specified.

2.Fabrication of samples

Eda et al.2) compared three different casting methods, centrifugal casting method using gas and oxygen blowpipe, high frequency and argon arc casting methods. The result showed that casting temperature increased by using a blowpipe, affecting the cast surface. In the present study, Cascom KDF, a casting apparatus that melts metal by a ceramic heater in an argon atmosphere was used. Casting with high precision was achieved by controlling the melting temperature and avoiding oxidation during casting with this machine.

3.Attractive force measurement

Vertical displacement control is important. Previous retention studies have demonstrated that a lateral displacement may not be well controlled and would advsersely affect any measurements. The magnetic assembly must not laterally slide on a keeper, and is pulled in a vertical direction perpendicular to the adhesive surface in order to ensure accurate measurements of maximum attractive force for a magnetic attachment. A custom-made jig with a vertical bearing control was used. A magnetic attachment was vertically displaced in a controlled manner and direction using this jig. The adherant attractive surfaces of the sample and magnetic attachment were pulled off in a vertical direction.

4.Results

Okamoto et al.3),4) reported that a magnetic force is exerted by addition of cobalt to Attract P. A magnetic attachment keeper was fabricated using ingot of castable dental alloy. An attractive force decreased with an increase of pre-cast ingot proportion increased to the virgin metal quantity. This finding was attributed to be due to increased content of cobalt in the cast alloy.

Although no increase in casting defects were observed by the repeat casting of an alloy, there is a potential of contamination with oxides attached to a cruicible.

Retentive force achieved in the present study was between 250 and 300 gf. Further studies are required to investigate additional designs and casting methods of Attract P that might achieve added attractive force.

Further

examination regarding surface properties and composition of the alloy is

necessary in order to confirm the cause of the noted decrease in the attractive

forces measured.

Conclusions

A magnetic attachment keeper was fabricated using a ingot of castable magnetic dental alloy (Attract P®, TOKURIKI-HONTEN Co.), and the following results were achieved.

A decrease in the attractive force was observed with a pre-cast ingot content of more than 75%.

There

was no change in the cast defect with an increase of hearth content.

References

1. Y.TanakaFMagnetic AttachmentC94-112CIshiyaku Publishers,IncCTokyoC1992D

2. K.Eda, Y.Okamoto,K.Miyazawa,S.NaruseFSurface Structure and Properties of Casting Pd-Co-Ag Alloys with MagneticsCJSDMD@vol.21No.4 2002

3. Y.Okamoto, K.Eda, K.Miyazawa,S.NaruseFBasic Study of Casting Alloys with MagneticsCJSDMD@vol.17 No.5 1998D

4. Y.Okamoto, K.Eda, K.Miyazawa,S.NaruseFA Casting Pd-Co-Ag Alloy with MagneticsCJSDMD@vol.18 No.2 1999